Skip to content

sdsf

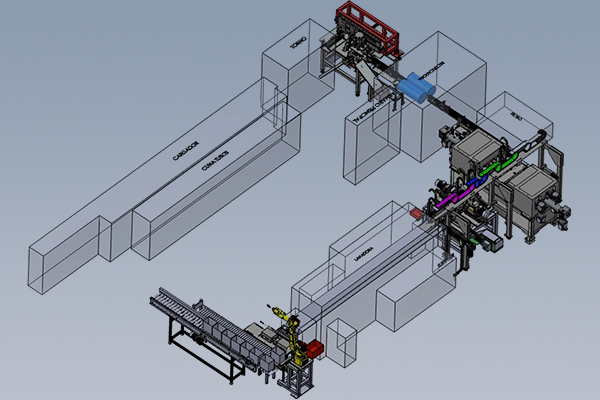

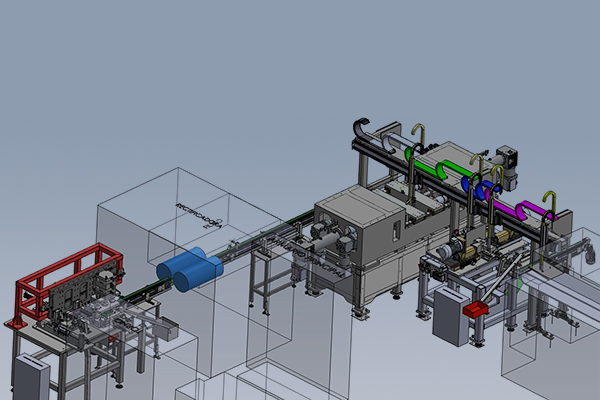

- Integration of standard machinery and custom machinery.

- Line adapted to tube lengths up to 250mm and diameters between 20-30mm.

- Complete manufacturing process, with tube cutting machine, turning, punching, grinding, end reducer, artificial vision control of punching, facing, washing and degreasing, control of facing faces by artificial vision, and robotic storage.

- Cycle time: 5.5 seconds/piece.

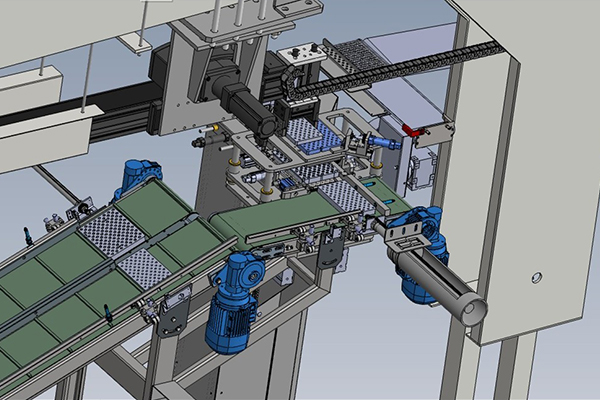

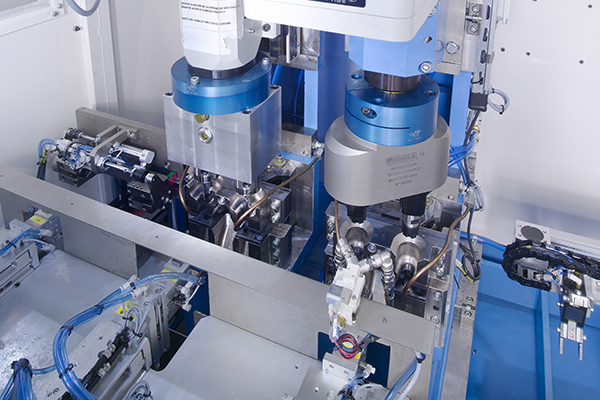

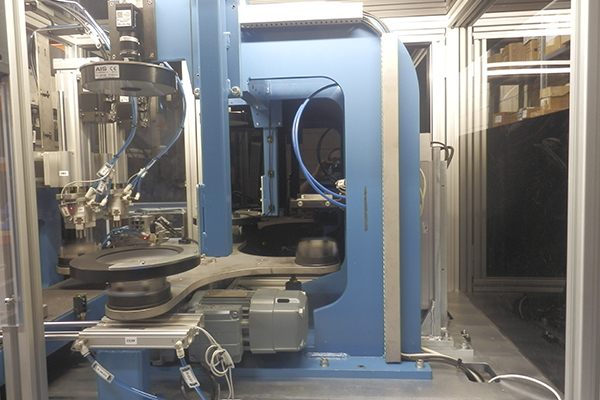

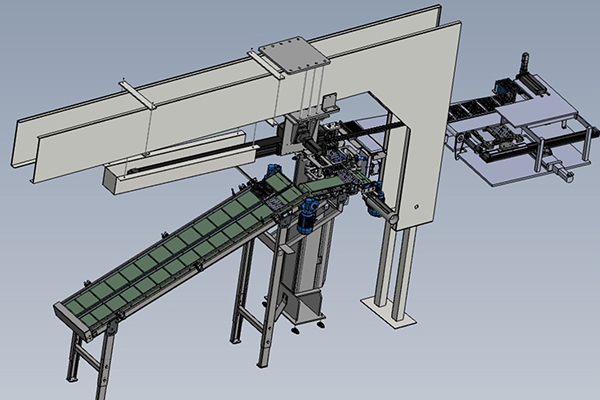

- Linear motor gantry handling.

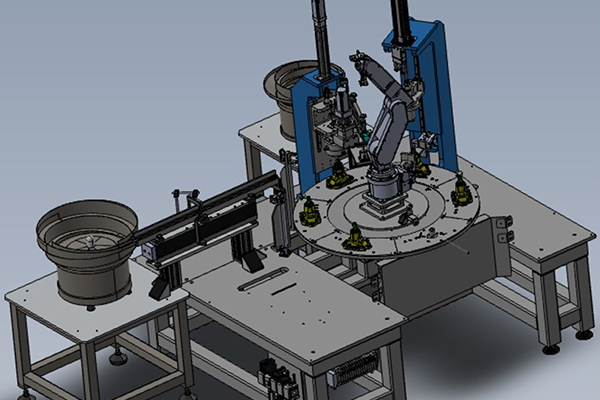

- 6-position rotary plate.

- Interchangeable tools to work with 10 different references.

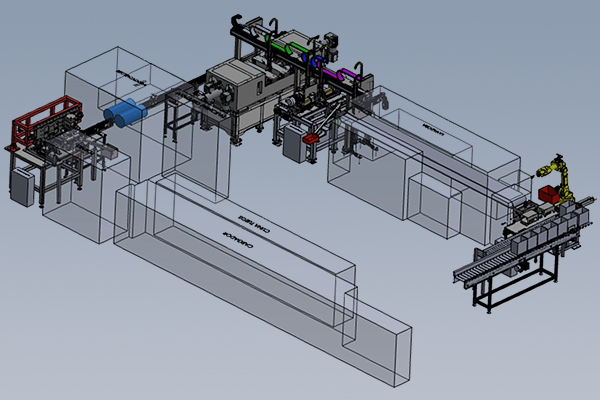

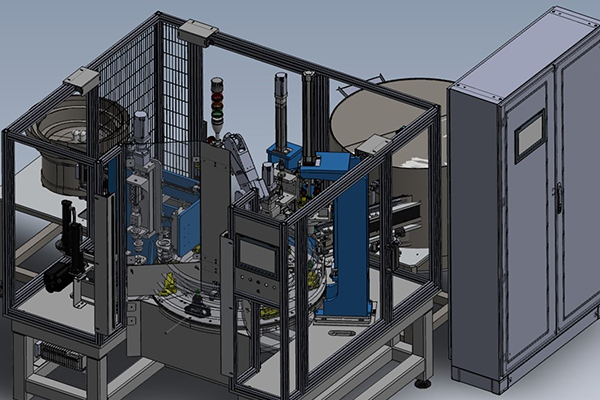

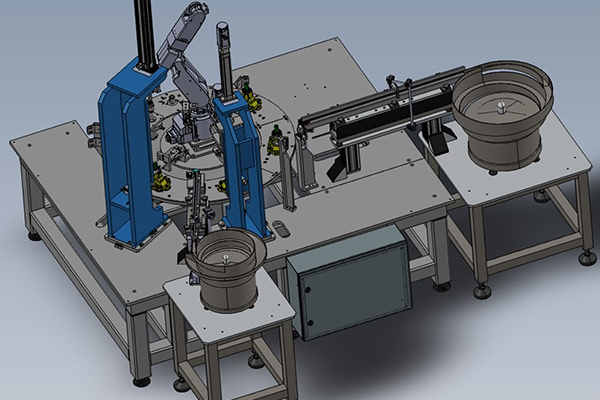

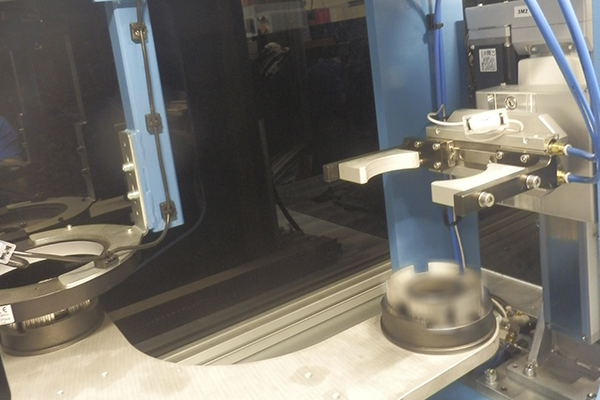

- Assembly of 7 components, with automatic feeding of 5 of them, including central handling robot.

- Insertion of clamping ring, insertion and rotation of tightening nut and insertion and positioning of plastic tabs.

- Automatic assembly cycle time: 50 seconds.

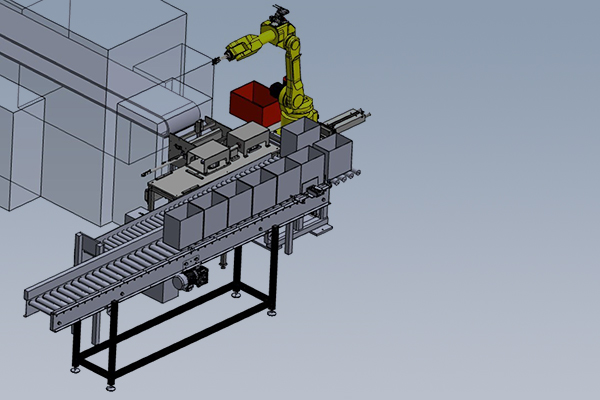

- Automatic feeding of parts from bulk container. Integration of empty container system and vibrating systems with discriminated positioning for handling.

- Execution of part machining.

- Cycle/piece time: 8.5 seconds.

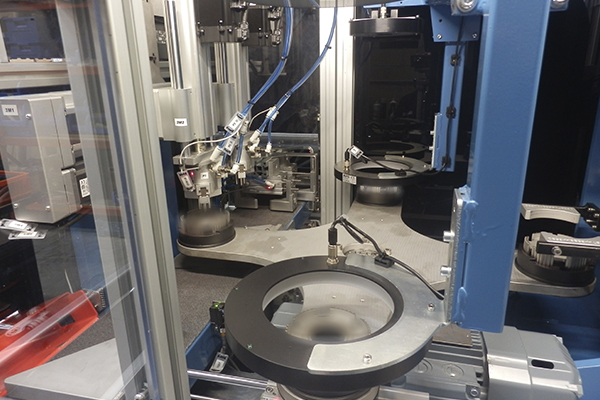

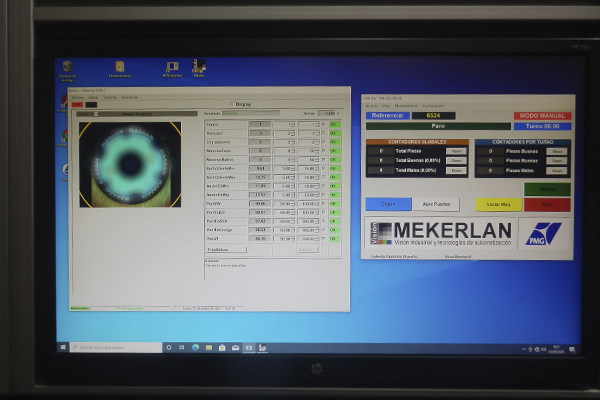

- Control by artificial vision of dimensions, geometric positions and surface finishes.

- Sorting of Ok/NOk parts to containers.

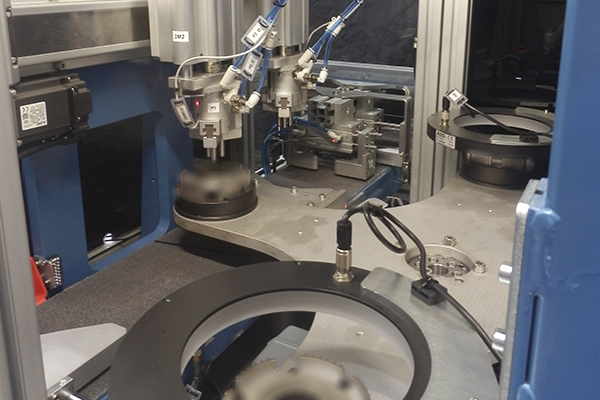

- Double electric load-unload handler.

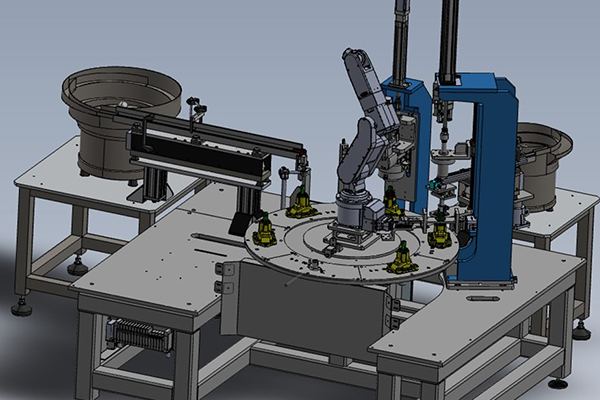

- 4-station rotary plate.

- 2 artificial vision systems for dimensional and surface control.

- 180º part rotation position.

- Piece cycle time: 3.5 seconds.

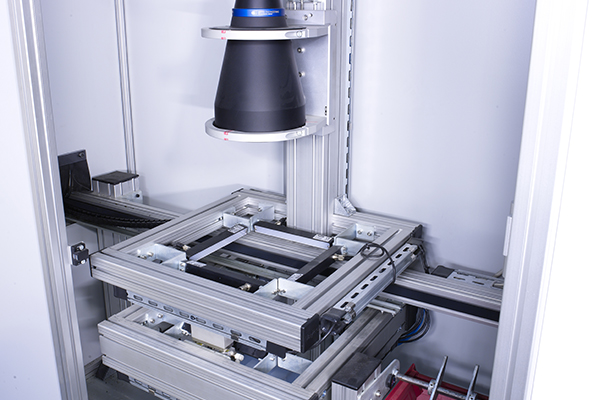

- Mixed transfer between plates 88-120 units or 120-120 units.

- Handling and feeding to the next process operation.

- Recovery of empty plates to new load.

- Cycle time of 13 seconds / plate.