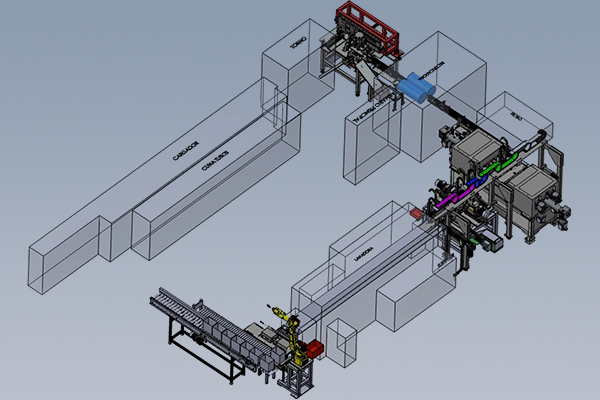

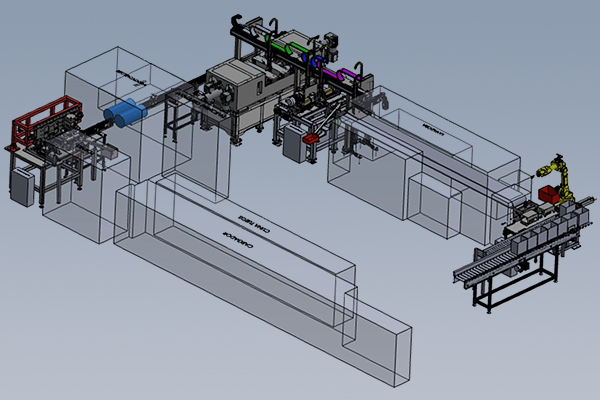

- Integration of standard machinery and custom machinery.

- Line adapted to tube lengths up to 250mm and diameters between 20-30mm.

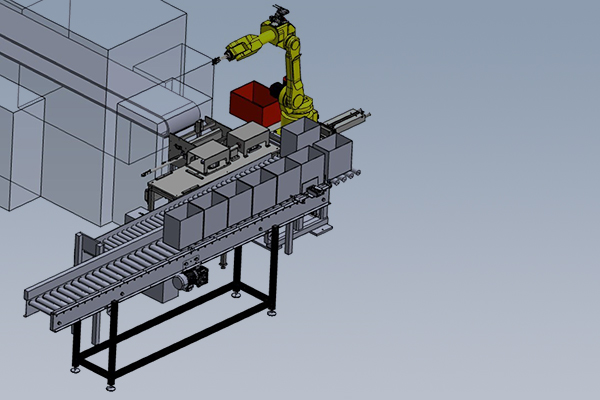

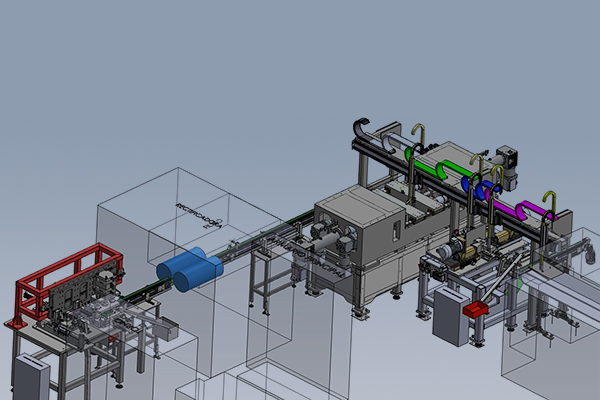

- Complete manufacturing process, with tube cutting machine, turning, punching, grinding, end reducer, artificial vision control of punching, facing, washing and degreasing, control of facing faces by artificial vision, and robotic storage.

- Cycle time: 5.5 seconds/piece.

- Linear motor gantry handling.

MANUFACTURING LINE FOR TUBULAR AUTOMOTIVE COMPONENTS